INDIANAPOLIS–(BUSINESS WIRE)—PolyCycle Innovation LLC (PolyCycle Innovation) has developed a post-consumer recycled (PCR) resin, Polycycle®. Using its proprietary technology, recycled plastics are sourced from our partners in North American recycling organizations and processed into a PCR resin that can be used in food and beverage closures. Through its exclusive partnership with Closure Systems International Inc. (CSI), caps and closures made with up to 100% Polycycle® are circulating in the market and are available in many different products. Floyd Needham, President and CEO of CSI stated: “The development of this unique resin has created opportunities for us to provide a ‘Closed Loop’ sustainable solution to support our customer’s stated ESG goals. The performance characteristics and flexibility of the material allow us to provide our customers with a customizable product that support their brands. As a result, we have commercialized the world’s first Carbonated Soft Drink closure utilizing PCR resin, all thanks to PolyCycle®.”

PolyCycle® uses a process to eliminate residual contaminants from PCR materials to provide a Closure-to-Closure™ PCR resin that meet or exceed organoleptic performance of virgin resins therefore reducing the reliance on virgin materials. Brad Bennett, Vice President and Chief Technology Officer of PolyCycle® Innovation says, “PolyCycle® Innovation has created an FDA approved manufacturing process with sustainability in mind. Closures incorporating PolyCycle® are 100% recyclable at all standard recycling centers, helping to divert solid waste from landfills and contributing to a truly circular economy for caps and closures. We are excited about the current opportunities and future development of this product.”

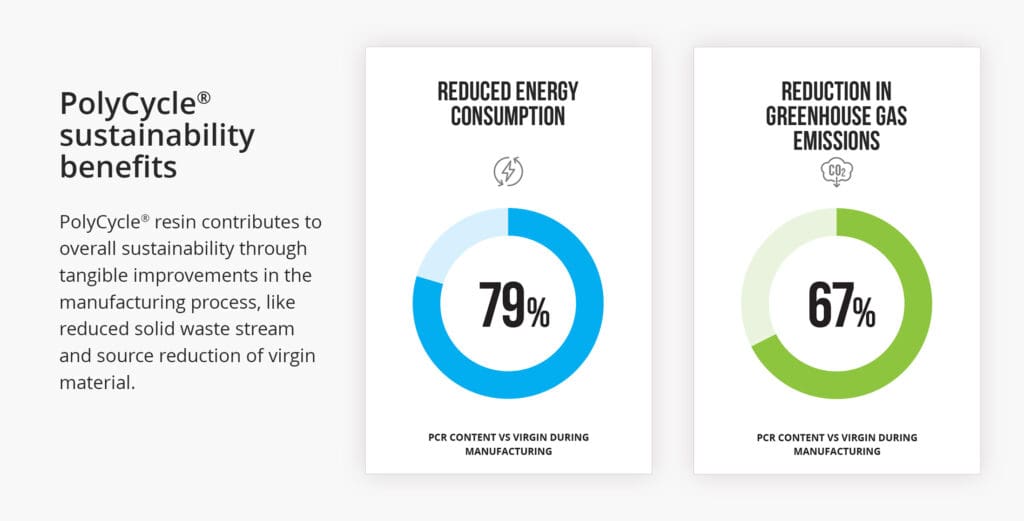

PolyCycle® offers many sustainability benefits for customers

PolyCycle® closures enable companies and brands to achieve their sustainability goals by reducing energy consumption by 79% during the resin manufacturing process and producing 67% less GHG emissions than virgin resin (conventional HDPE). Because of these improvements over traditional virgin plastic closures, PolyCycle® closures support sustainability and environmental goals. PolyCycle’s® PCR resin will enable CSI customers to comply with packaging requirements legislation, such as the California SB 54 bill, and extended producer responsibility requirements.

PolyCycle® receives GreenCircle Certification

PolyCycle® Innovation is excited to announce that PolyCycle® PCR resin recently received a certification from GreenCircle, an unbiased third-party auditor. The certification confirms that PolyCycle® PCR contains 100% post-consumer recycled content. PolyCycle® PCR resin allows CSI to be included on GreenCircle’s “Brands You Can Trust” list as a result of PolyCycle Innovation receiving this certification. Outside certifications like GreenCircle are important because they provide independent verification from objective third parties that apply the same standards to all certificate qualifiers. This certification provides credibility to potential customers that PolyCycle® PCR closures truly contain 100% recycled material.

“With global scrutiny on packaging innovation and sustainability claims, credibility is critical at CSI. Understanding that our products help brands build equity with their stakeholders and certified products deliver added value, CSI looked to GreenCircle to provide the ultimate stamp of approval,” said Richard Burt, Vice President of Business Development and Sustainability at CSI.

“GreenCircle’s robust auditing process and certification program supports our business need to provide the assurance required to source 100% PCR and close the loop for a truly circular economy for caps and closures. We greatly value their thorough process and partnership,” he added.

PolyCycle® performance excels

Closures can be made with up to 100% PolyCycle® PCR resin depending on the packaging type constraints. CSI has tested PCR closures incorporating between 30% and 100% PolyCycle® resin to prove that high levels of PCR resin content do not impact manufacturing, quality, or performance. Compared to virgin resin, PolyCycle® PCR resin meets or exceeds all closure performance requirements, including taste & odor, environmental stress crack resistance (ESR), dimensional stability, and CO² retention.

PolyCycle® provides many closure options

PolyCycle® PCR closures are available in both polyethylene and polypropylene materials to suit many different customer needs. CSI closures with PolyCycle® PCR resin can also meet brand requirements for color matching. PolyCycle® closures are available in a variety of market segments, including still and sparkling water, carbonated soft drinks, non-carbonated beverages, liquid dairy markets, food, personal care and pharmaceutical applications. All CSI stock closures can be made with PCR content, and CSI also has the ability to make custom closures with various percentages of CSI content as well. The CSI sales team can provide more information about procuring caps and closures made with PolyCycle® material upon request. To learn more about PolyCycle® closure options and the manufacturing process, view the PolyCycle® introductory video produced by CSI. Watch Video

About PolyCycle Innovation

PolyCycle Innovation LLC, a company started by Closure Systems International Group, Inc. is based in Crawfordsville, Indiana. PolyCycle manufacturers high-density polyethylene and polypropylene post-consumer resin (PCR). PolyCycle® PCR is derived from 100% recycled food and beverage packaging and sourced from recycling partners across North America.

PolyCycle’s® PCR technology helps create a true circularity economy, offering material that is Closure-to-Closure™. PolyCycle® PCR enables customers to achieve their sustainable packaging goals and comply with legislation. PolyCycle® uses a mechanical recycle process to eliminate residual contaminants providing customers products that meet or exceed organoleptic performance of virgin resins. PolyCycle® PCR can be used in a wide array of products including foods, beverages, dairy products, nutraceuticals, vitamins, pharmaceuticals, personal care and more.

About Closure Systems International, Inc.

Closure Systems International Inc. (CSI) is a global innovator in the design and manufacturing of sustainable closure solutions. Covering a wide range of applications across consumer and industrial markets, CSI provides unparalleled customer and technical services for high-speed application systems. Our industry leading Research & Development team can conceive and construct bespoke capping equipment to meet your product and operational goals. Major categories served include carbonated soft drinks, bottled water, juices, isotonics, teas, adult beverages, dairy, foods, pharmaceutical and automotive fluids. CSI’s cutting-edge closure solutions help customers maximize profits by enhancing the sustainability and desirability of their brands and optimizing their total cost of operations. From compliance to consumer satisfaction and resource conservation to circular economies, CSI designs our products to enhance your products, helping customers meet their environmental and social responsibility goals. CSI is headquartered in Indianapolis, IN, and produces 50+ billion closures annually across its 8 manufacturing sites.

For further information, please contact:

Closure Systems International

Richard Burt

Vice President Business Development

7820 Innovation Blvd, Suite 100

Indianapolis, Indiana 46278 USA

(901) 821-2252

csifeedback@csiclosures.com