What CPGs Producers Need to Know about Extended Producer Responsibility (EPR) Laws

Extended Producer Responsibility (EPR) laws are transforming the packaging industry by assigning brands greater responsibility for the environmental impact of their products throughout their lifecycle. Instead of leaving waste management to municipalities, these regulations put the obligation on producers to make smarter, more sustainable packaging choices. This shift encourages the use of sustainable materials and designs as well as circular economy practices like mass commercial recycling, to reduce reliance on virgin plastics and avoid pollution.

The growing number of U.S. states adopting EPR laws reflects a global push to improve materials management through responsible production and consumption.

EPR Legislation in the United States

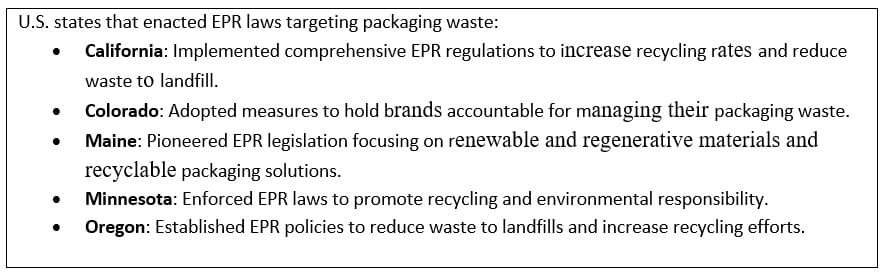

As of February 2025, five U.S. states have enacted Extended Producer Responsibility (EPR) laws: California, Colorado, Maine, Minnesota and Oregon.

Other states like Tennessee, Connecticut, Hawaii, Massachusetts, Nebraska, New Jersey, New York, and Washington have proposed EPR legislation, with potential enactment in 2025-2026. This trend mirrors efforts in European countries, requiring more businesses to rethink their packaging strategies sooner rather than later.

Sidebar:

PolyCycle PCR Resin: Aligning with EPR Objectives

Closure Systems International’s (CSI) award winning designs, made with PolyCycle, a certified post-consumer recycled (PCR) resin, assists brand owners in addressing EPR directives. Put simply, PolyCycle helps brands reduce their product carbon footprint while staying ahead of evolving regulations.

PolyCycle EPR-related features include:

- Post-Consumer Recycled Materials

PolyCycle is mechanically recycled PCR resin which we source domestically. Through vertical integration CSI and PolyCycle help develop necessary infrastructure to improve access to residential recycling and improve recovery and collection rates. - FDA-Approved for Food and Beverage Applications

PolyCycle PCR resin is FDA compliant for food and beverage applications while offering sustainable packaging solutions. It ensures compliance with both EPR and FDA regulations supporting industries like food, beverages, dairy, nutraceuticals, and personal care. - Enhancing Circular Economy Initiatives

All closures and packaging produced from PolyCycle are designed to be 100% recyclable, supporting streamlined material recovery and reuse. Packaging components made of PolyCycle PCR are intended to be recovered and recycled back into packaging, a process that supports a closed-loop system where recycled materials are continuously repurposed rather than discarded, keeping plastics in the economy and out of our environment. - Lightweight Closure Designs

CSI specializes in designing lightweight closures that use less plastic without compromising functionality. For brands producing millions of closures a year, even small reductions in plastic use can make a huge environmental difference — significantly decreasing virgin plastic use while supporting compliance with EPR regulations. - Impact Pathways Model

CSI’s sustainability initiatives focus on three Impact Pathways: Product Stewardship, Responsible and Efficient Operations, and Partnership for Sustainable Progress. This comprehensive approach aligns with EPR policies to reduce waste and promote a circular economy.

Why Manufacturers Should Consider PolyCycle

Integrating PolyCycle PCR resin into packaging offers manufacturers a proactive approach to addressing EPR regulations while reinforcing their commitment to sustainability. Benefits include:

- Regulatory Compliance: PolyCycle enables manufacturers to meet evolving EPR regulations, reducing potential liabilities associated with non-compliance.

- Environmental Impact: By reducing reliance on virgin plastics and enhancing recyclability, PolyCycle contributes to waste reduction and supports environmental sustainability goals.

- Product Integrity: PolyCycle ensures that packaging maintains high-quality standards without compromising production, functionality or appearance, even with increased recycled content.

For companies looking to future-proof their packaging, PolyCycle offers a straightforward, sustainable solution that meets both regulatory demands and consumer expectations.

Contact CSI to explore how PolyCycle PCR resin can support your packaging goals and meet EPR regulations: https://bit.ly/3ufypmh.

What is PolyCycle PCR?

PolyCycle PCR (Post-Consumer Recycled) is a high-quality resin that is made entirely from recycled plastics. This resin is specifically designed for sustainable packaging applications. PolyCycle PCR is FDA-compliant for food-grade use and GreenCircle Certified for its post-consumer recycled content, making it a top choice for companies seeking to reduce their environmental impact.

How does PolyCycle PCR benefit the environment?

PolyCycle PCR helps significantly reduce greenhouse gas emissions, lowering emissions by up to 70% when compared to virgin resin. By promoting recycling and reuse, PolyCycle PCR contributes to a circular economy by reducing landfill waste, conserving natural resources, and minimizing the environmental footprint of plastic products.

Why should my company use PolyCycle PCR?

Using PolyCycle PCR not only helps reduce the environmental impact of your packaging but also allows your company to meet sustainability goals, improve its brand image, and comply with environmental regulations. It’s a smart choice for companies looking to make a lasting impact on the planet while maintaining high-performance standards in their products.

Can PolyCycle PCR help companies stay ahead of environmental regulations?

Yes. With increasing environmental regulations requiring the reduction of virgin plastic use, PolyCycle PCR enables companies to help meet these requirements while improving their sustainability profiles. Adopting PolyCycle PCR today helps future-proof businesses against evolving regulatory demands and position brand leadership in sustainable practices.

Recent Comments