Whether you’re new to the world of caps and closures or just looking for a refresher course, getting to know the industry terminology can be overwhelming. To help you out, we’ve compiled a list of definitions of the most common terms used in the packaging industry. Here are the words you need to know:

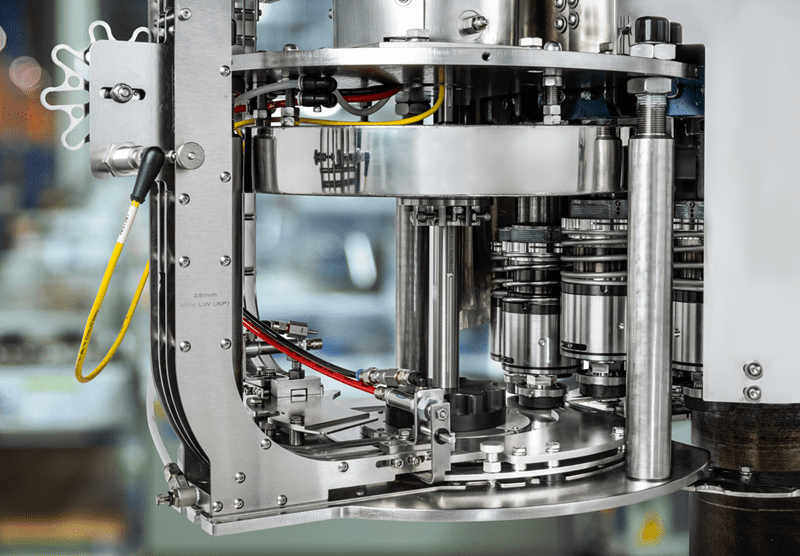

CAPPING EQUIPMENT

Capping machines

Capping machines automate the entire capping process to ensure consistency and efficiency. CSI makes various capping machines to suit a wide variety of manufacturing needs.

Cap handling machines

Cap handling machines move and sort closures to get them ready to be fed into the capping machine. CSI makes several different cap handling machines to suit a wide variety of manufacturing needs.

Headsets

The headset is the apparatus that picks up, positions, and attaches each closure. CSI offers multiple kinds of headsets: the XT6 headset, the HT6 headset, the HT10 headset, the VK138 headset, and the VK900 headsets.

Chucks

The chuck is the part of the headset that actually holds the cap and screws it onto the bottle. CSI offers multiple diameters of standard chucks as well as a Flex-Chuck that can be adjusted to fit different size caps.

CLOSURE MATERIAL TYPES

Aluminum

Aluminum is a lightweight silver-white metal that is commonly used as a cap for glass bottles. It can also be used to make bottles and other forms of packaging.

CoPolymer

CoPolymer is a plastic made of two or more monomers, or types of molecules. CoPolymers can have many different properties depending on the component molecules.

Polypropylene

Polypropylene is a thermoplastic polymer made of propylene. It is resistant to higher temperatures and is very lightweight.

Polyethylene

Polyethylene is a thermoplastic polymer made of ethylene. It is resistant to lower temperatures and can be very flexible when necessary.

TYPES OF CLOSURES

1 piece

One-piece closures are lightweight caps that lack a liner, making them a cost effective and environmentally sustainable choice.

2 piece

Two-piece closures feature a plastic cap shell and a separate liner, usually made from ethylene vinyl acetate, for extra sealing properties.

Tamper evident

Tamper evident closures are designed to provide auditory and visual cues when a product is opened via created barriers to entry, such as a seal that must be opened in order to access the product. They also provide visual evidence that unauthorized access or tampering has occurred prior to it reaching the consumer.

Child resistant

Child resistant packaging, sometimes called “special packaging,” is designed to reduce the risk of poisoning of children by making it more difficult to open certain pharmaceutical, pesticide, and household chemical products. The U.S. Consumer Product Safety Commission (CPSC) has the authority to regulate child resistant packaging under the Poison Prevention Packaging Act.

CLOSURE SIE AND FINISH

Size

Size refers to the diameter of the closure or cap. It is usually expressed in units of millimeters (mm).

Finish

Bottle finish refers to the area above the neck of a bottle, including the lip, collar, and threads for a cap. The term is a holdover from glassblowing days, when the final step in creating a glass bottle was to “finish the lip” by removing it from the blowpipe and finishing off the edge.

MOLDING PROCESS

Compression molding

Compression molding involves pouring thermoset material into a heated mold, then compressing it under pressure until the plastic takes the desired shape.

Injection molding

Injection molding involves injecting the raw material into an existing mold cavity, where it is left to cool until it has hardened.

BOTTLE AND PACKAGING TYPES

Aluminum bottles

Aluminum bottles are less popular than aluminum cans, but they are slowly catching on in popularity due to the fact that aluminum can be recycled an infinite number of times.

Cartons

A carton is a container made of waxed paperboard that comes with a plastic spout. Cartons are an excellent eco-friendly packaging choice due to the minimal plastic used in their construction as well as the fact that they can be recycled at paper or cardboard facilities.

Glass non-returnable bottles

Glass non-returnable bottles can be used once before they must be returned to the factory to be melted down and made into new glass bottles.

Glass returnable bottles

Glass returnable bottles can be sterilized and refilled without melting them down and reforming them first.

HDPE

High Density Polyethylene is a polyethylene thermoplastic made from petroleum. It is a popular choice for bottles and other packaging and can be recycled into products like composite wood and plastic lumber.

HDPE non-returnable bottles

HDPE non-returnable bottles can be used once before they must be returned to the factory to be melted down and made into new plastic products.

PET non-returnable bottles

PET is a thermoplastic polymer resin from the polyester family. PET non-returnable bottles can be used once before they must be returned to the factory to be melted down and made into new plastic products.

PET returnable bottles

PET returnable bottles can be sterilized and refilled without melting them down and reforming them first.

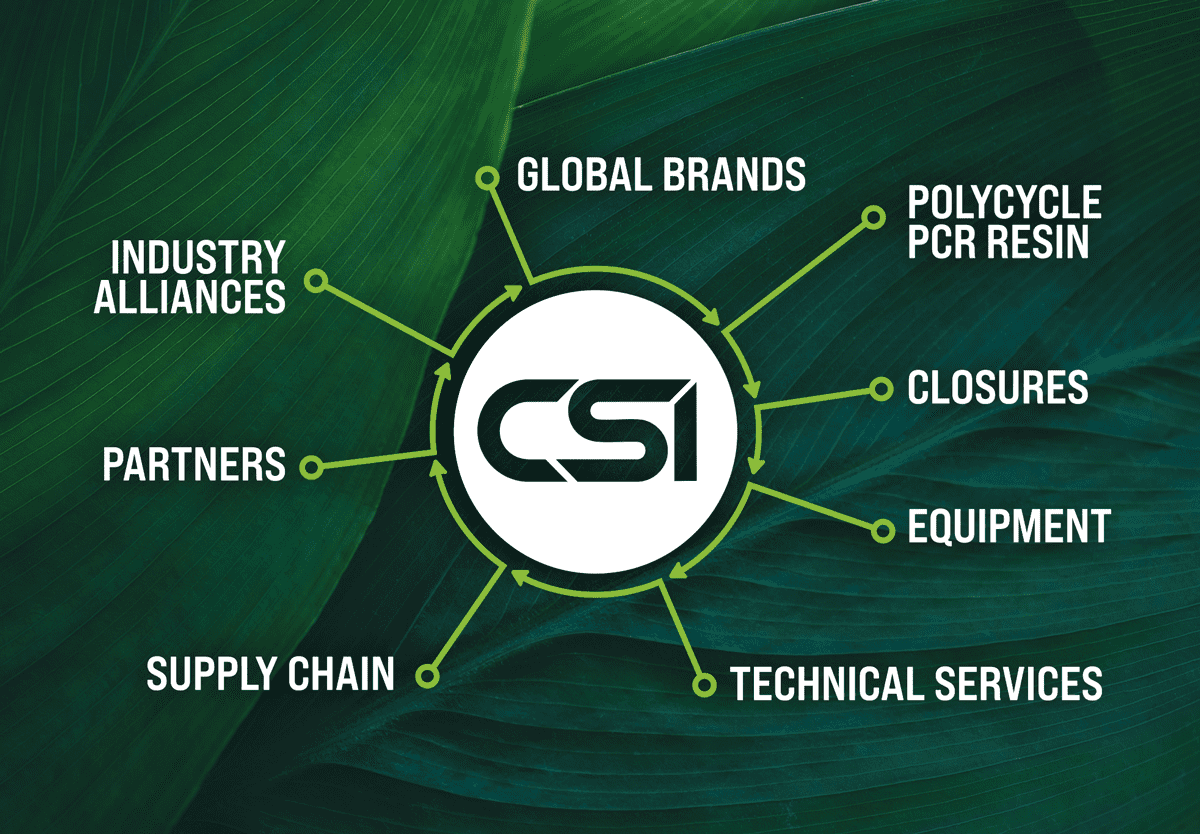

Ready to take the next step for your closure or capping equipment solution? Inquire about a custom closure here, or learn more about our capping machines here.

Recent Comments