At Closure Systems International (CSI), we know that getting the most out of your manufacturing equipment goes well beyond the initial installation and set-up. That’s why we offer four different technical support programs:

- Headset Exchange

- Spindle Exchange

- PlasTech Training

- PM Select Preventative Maintenance

In this guide, we’ll explore the benefits of technical maintenance services for manufacturing equipment and explain each of the four services that CSI offers in detail.

Benefits of technical support programs

Technical services like the programs offered by CSI offer many benefits to clients. For one, preventative maintenance measures reduce unplanned downtime caused by equipment failures. They also reduce set up and changeover time since the maintenance is scheduled in advance and can be performed in optimal conditions.

Technical service programs also increase equipment speed and efficiency as well as decrease the number of misapplications, which in turn helps to reduce scrap. Preventative maintenance also helps to keep equipment running for longer, further reducing operating costs and contributing to sustainability goals. Taken together, these effects increase revenue and help your business to turn a profit.

CSI technical support programs

CSI offers four technical support programs: headset exchange, spindle exchange, PlasTech training, and PM Select preventative maintenance. Companies can pick and choose which services make the most sense for them, or enroll in the PM Select program if they want to get a variety of services through one preventative maintenance program.

Headset exchange

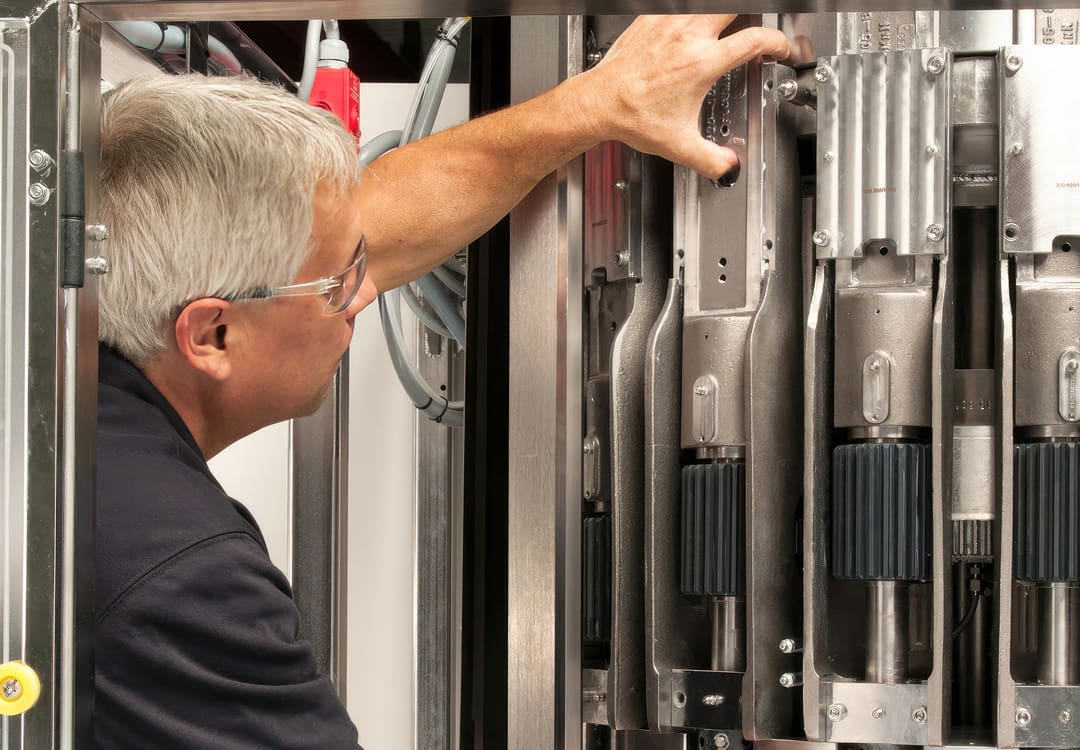

Qualified CSI Field Service Representatives visit each bottling plant to exchange the current capping headsets for CSI reconditioned headsets on a regular basis in the Headset Exchange Program. Headsets are maintained, adjusted, and precisely calibrated to fit the bottler’s specific line conditions and exchange intervals are determined based on bottling line volumes and usage.

Spindle exchange

Similar to the headset exchange program, CSI’s Spindle Exchange Program employs qualified technicians to swap a bottling plant’s capping spindles for CSI factory reconditioned spindles. Just like the headsets, spindles are maintained, adjusted, and precisely calibrated to fit the bottler’s specific line conditions and exchange intervals are determined based on bottling line volumes and usage.

PlasTech

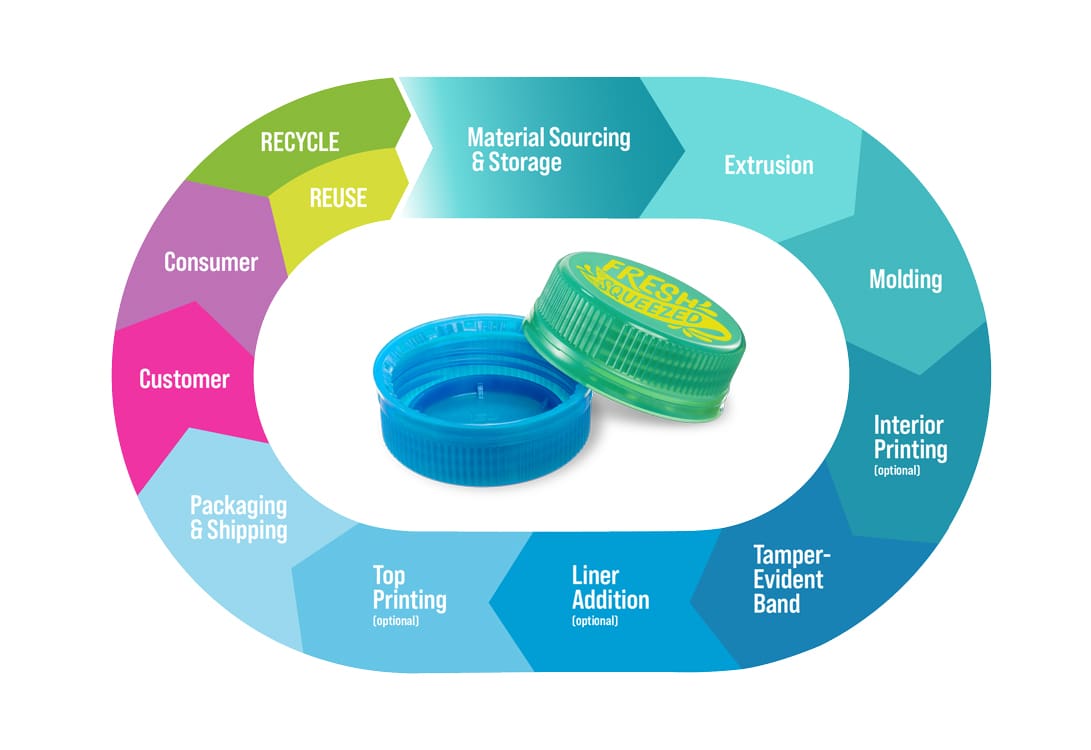

CSI’s PlasTech training course is designed to get your staff up to speed on the fundamental details of package manufacturing. PlasTech training covers topics such as closure sealing mechanisms, inspecting vendor-supplied materials, full package testing, recognition of closure application defects, and more. PlasTech training can be conducted at CSI’s training facility or the client’s location; when the class is conducted at the client’s facility, we will tailor the course to your company’s specific needs.Hundreds of companies and individuals have benefited from the application expertise that CSI has shared in PlasTech Training over 25+ years.

PM Select

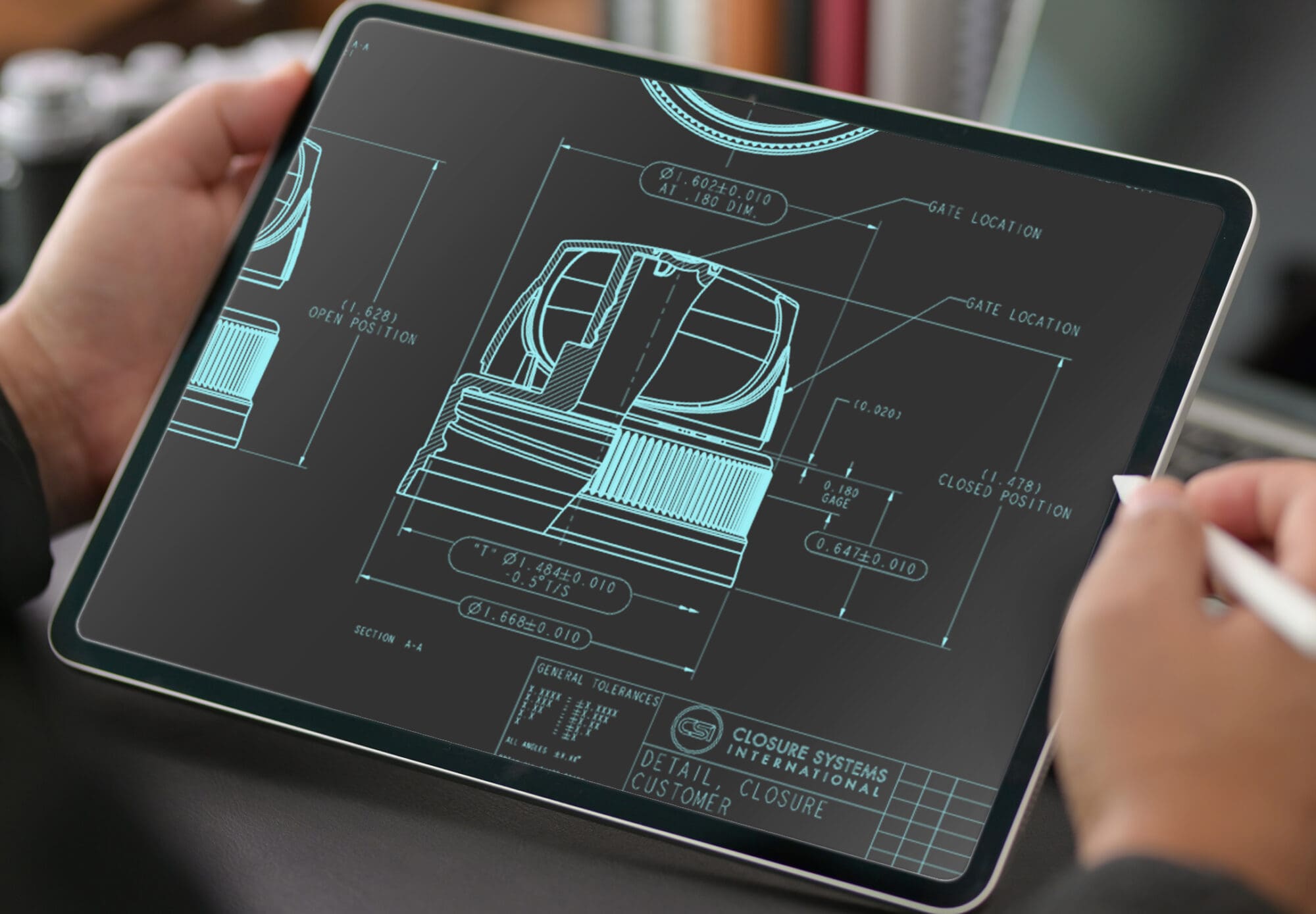

Closure Systems International’s PM Select program is a customized preventative maintenance program offering bottlers maximum flexibility and cost savings. The program includes four pre-planned CSI technical service visits per year, providing guaranteed priority scheduling while locking-in significant parts and service savings. You can choose from a variety of technical services, not just headset and spindle exchange or PlasTech training but also capper audits, capper rebuilders, capper assessments, and capabilities studies. Multiple services can also be performed in a single service call to maximize your company’s savings on parts and service.

Ready to learn more about how CSI’s technical support plans can benefit your manufacturing plant? Contact us today to discuss your maintenance needs and get a service quote.

Recent Comments