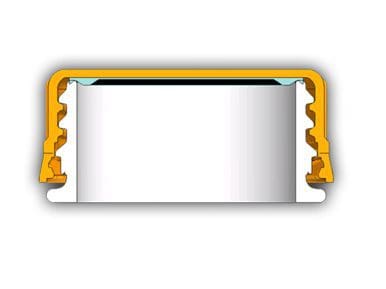

The Extra-Lok V 38mm ODU unique “Triple Seal” closure liner geometry securely seals both PET and HDPE bottles despite finish distortion that can be inherent with hot-fill applications. The light-weight design also offers application efficiency, reducing the total cost of operations.

Lightweight “Universal” Design

- 38mm, 2-piece / lined, double lead thread, HDPE closure

- 18%+ lighter than competitive 38mm 2-pc designs

- “Triple Seal” design securely seals PET and HDPE

- Compatible with 1843, 1845 and similar PET bottle finishes (0.060” –0.100” finish wall thickness)

- Compatible with 1842 and similar HDPE bottle finishes

- Other finish wall thicknesses considered on a case-by-case basis

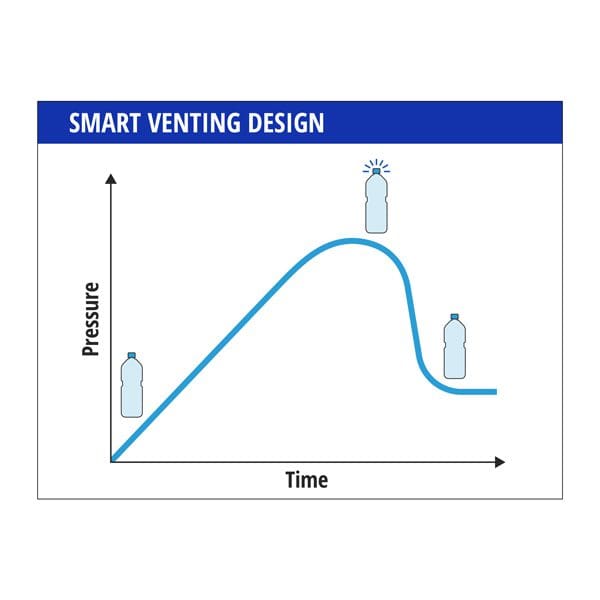

- Early pressure release results in longer thread engagement after venting for maximum anti-blow-off security

- Secure tamper evidence for product and consumer safety

- Consumer-friendly, consistent removal torques

- Debossing, top printing, UTC promo and color options for enhanced brand marketability

Reduces Total Cost of Operations

- Broad application window and robust performance

- Universal seal geometry helps minimize finish distortion inherent with hot-fill PET bottles

- Molded-in liner for maximum flexibility, accommodating plastic bottle finish variability

- Less maintenance, more productivity

- Energy saving, no steam application for improved capping efficiency

- In addition to quality closures, CSI provides capping equipment and technical services, globally.

- CSI’s closure systems solutions help customers maximize profits by increasing the marketability of their brands and optimizing their total cost of operations